By Bill Bregar

SENIOR STAFF REPORTER

Published: November 6, 2014 9:32 am ET

Updated: November 6, 2014 9:37 am ET

Image By: Data compiled by Hollee Keller, graphic by Jessica Jordan

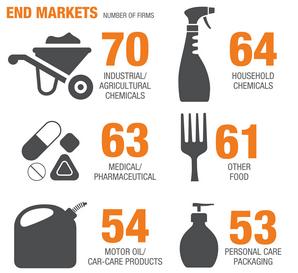

Top end markets for North American blow molders, according to data from Plastics News' annual blow molders ranking.

CHICAGO — U.S. blow molding demand for polypropylene and high density polyethylene should grow this year over the 2013 levels, Joel Morales, polyolefins director at IHS Chemical said at the SPE Blow Molding Conference.

Morales said PP will grow 9.9 percent in 2014 for blow molding. HDPE will increase 3.2 percent.

IHS thinks PET for blow molding will remain flat. Morales said blow molded bottles are a small part of the overall PET demand. Polyester fiber for clothing is the biggest market. “China’s really driving this thing,” he said.

Morales said the North American polyethylene market is “snug,” and is awaiting announced new capacity in the coming years, as petrochemical companies take advantage of low-priced ethane feedstocks from lower priced natural gas unlocked by hydraulic fracturing.

“It’s been a tough year for blow molding [PE] resin availability,” he said. “The market is tight.”

IHS is based in Houston.

|